TRIAC Dimmable LED Drivers

If you are searching for effective TRIAC dimmable LED drivers, then there’s no one better than boqi. With the optimization of designs and solutions, we can revolutionize your experience.

You can get the best possible way to turn your ideal product’s effect from imagination to reality. Contact us to get an instant quote.

14+ Years

Manufacturing Experience

1000+ Units

Each LED Driver in Stock

45+ Countries

Our clients over the world

99.9%

Satisfaction

Premium TRIAC Dimmable LED Drivers Manufacturer In China

With 14 years of experience, boqi is well versed in this field. Yes, you are dealing with masters. You can trust them with your needs and expectations.

Need proof? Why don’t you contact us, to get our catalog to know more about us.

- We are certified; boqi led drivers are CE and CB approved by TUV, also certified with SAA and RoHS.

- We will ensure that we only provide you with high-quality Dimmable LED Drivers.

- Our LED Drivers are very durable because we make them from 100% original brand components and test them 100%.

- We, as a brand, are genuine in all our dealings.

- Our LED Drivers are quite environmentally- friendly.

Want to know how we can do business? Let’s talk!

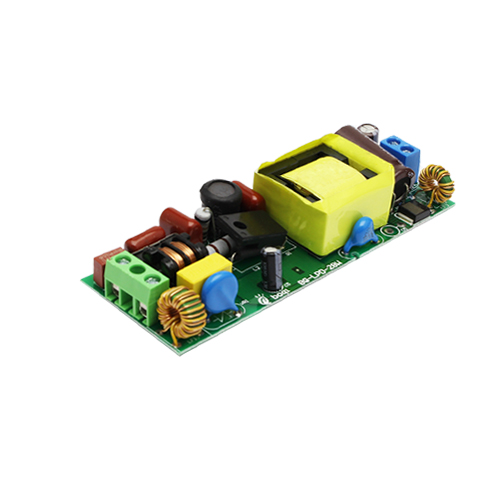

TRIAC Dimmable LED Drivers - Constant Current Mode

TRIAC Dimmable LED Drivers - Constant Voltage Mode

Still not finding what you're looking for?

Contact our consultants for more available products.

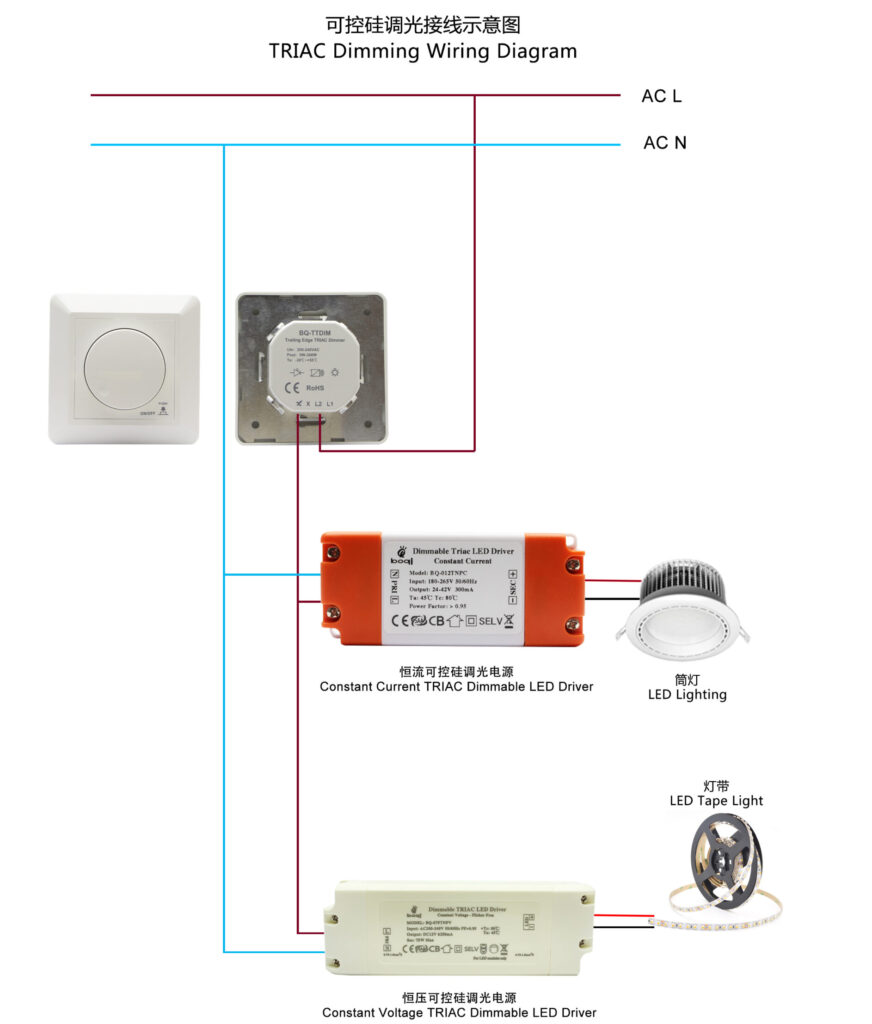

TRIAC Dimming Function - Wiring Diagram

Wiring TRIAC drivers is easy as before

Now there are 2 kinds of TRIAC dimming wirings, which is still as the traditional way like the right diagram showed. And another way is as follows, which is much easier to understand.

The interface of the LED driver: L/N (strong electric input); LED+/LED- (output interface, connect to the light)

Step 1: Connect L/N of the LED drivers to OUTPUT of the dimmer.

Step 2: Connect LED+/LED- of the LED driver to the input interface of the light.

Step 3: Connect the INPUT of the dimmer to electricity.

*Remark: Before powering on, check the DIP switch on the dimmer to make sure that the dimming mode (leading edge or trailing edge dimming) is compatible with the LED driver.

We have both these 2 types TRIAC Dimmers, which is compatible with 99% TRIAC dimmable LED drivers on the market.

F.A.Q

Yes, we had designed the TRIAC dimmable LED Drivers which are compatible with leading and trailing edge dimmers, which can say as forward and reverse phase-cut. And the new design-led drivers are going to instead of the old design items, which is with only trailing edge mode.

Yes, like our TRIAC LED drivers we have made the new design to improve to fit 2 modes. Our engineer team will optimize customized items’ design based on reasonability and efficiency.

Yes, we will provide the label printing service by laser machine. Just send us your logo and model, we will send you the drawing to confirm within 4 hours.

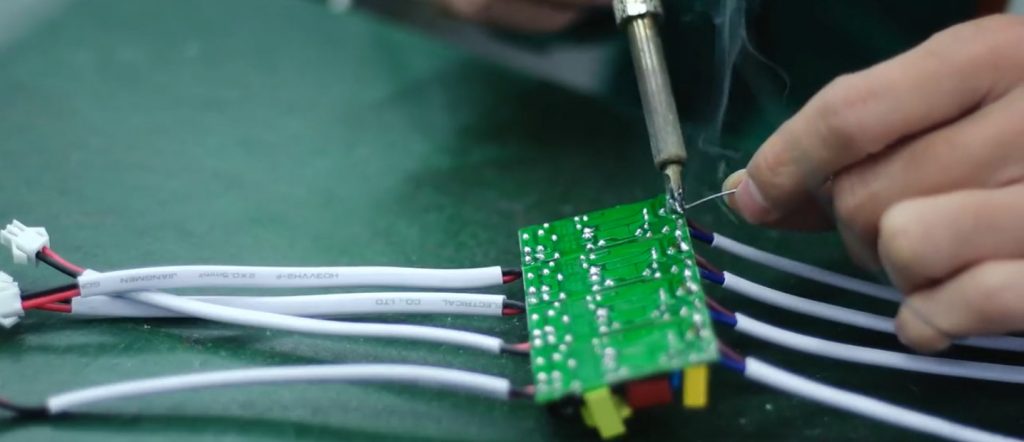

Yes, if necessary, we can assemble your wires on the led drivers. Also, we can purchase your needed wires to assemble.

Our LED drivers are with CE and CB issued by TUV, SAA and RoHs etc.

If the quantity are in stock, they will be ready to ship in 3-5 days.

Each LED driver will be wrapped with a foam cotton bag to avoid bumps, and then placed in a reinforced 5-layer corrugated box.

For small bulk goods, we will deliver them directly to you via DHL, FedEx, UPS, TNT. It usually takes 3-7 days.

boqi is a Professional LED Drivers Manufacturing Company That You Can Trust

Streamlined Supply Chain

To benefit from our all-in-one service starts from conception, samples, production, packing, finally shipping. My dear clients only need to wait for the goods delivered.

Self-Owned Factory

Positive after-sales service and solutions. Never shirk responsibility, our team will take the initiative to deal with problems

Goods in stock

We usually have the standard goods like TRIAC type, 0-10V type, DALI type, dimmers are in stock, and be able to ship in 1-2 days.

Save Cost

We will reduce your 20%-30% purchase cost by buying the matched LED Drivers with good quality, improving lightings' quality, win the best words of mouth.

Gapless Communication

You can communicate seamlessly with our English sales team, and your requirements will be transferred to the matched products or engineering team clearly.

Fast Response

You can get a quick quote within 4 hours. And we offer fast sample service, your samples will be sent out as fast as 3 days or less

High Precision

By hiring true professionals and not just standard workers to operate our production machines and testers, ensure you can get dimmable LED drivers with high precision data.

Positive Services

Positive after-sales service and solutions. Never shirk responsibility, our team will take the initiative to deal with problems

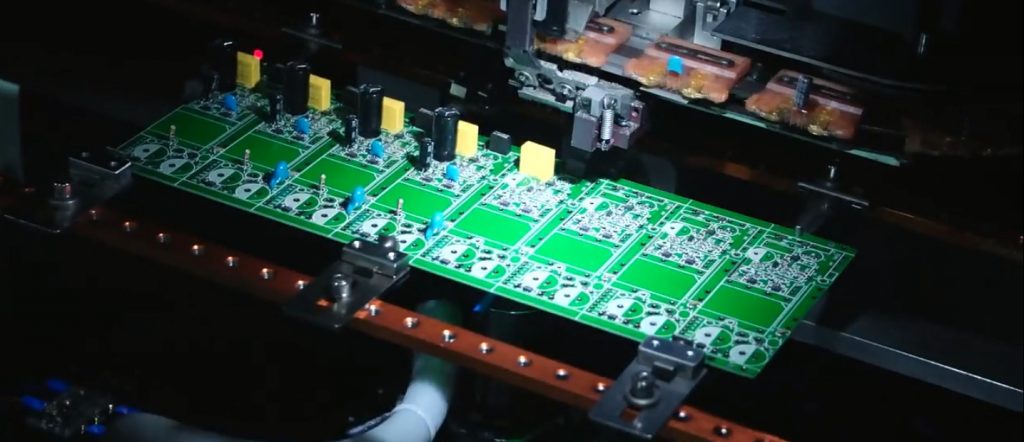

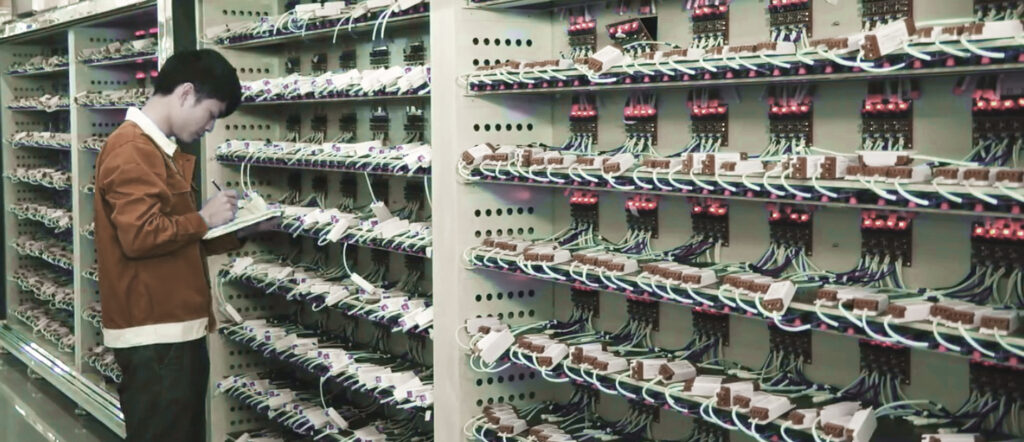

The Whole Process Of Producing LED Drivers

We made the circuit design by our engineer team via project evaluation and drawing steps. After the sample approval, we will start the production of the bulk orders. When we get the PCB that is produced according to our design, our testers will make a sampling inspection of them. Then, there are our production processing, Let’s look at

1. After the PCB is evenly coated with solder paste, The mounter will paste the components on its surface.

2. The plug-in machine inserts the components into the pasted circuit board.

We use the high precision mounter and plug-in machine, that maintain our production accuracy and efficiency.

3. The unfinished PCB will come into wave soldering device, gain the tin to fix all SMD and dip parts. Wave soldering is the best technique for soldering, which can ensure a high soldering rate and a clear soldering surface.

4. Manual repair welding shall be carried out for the missing welding on the plate.

5. Our quality engineers will test the specifications and function of the power supply by test room.

6. Conduct an aging test on the led drivers to evaluate if they are matched the quality standard, and promise the yield rate up to 99.5%.

Cilents & Feedbacks

boqi is a good partner for us. They provided a customer-made service for our projects. The best part of their service is to improve the design based on ours and give much good advice to us, then keep every detail as what we talked about.

Fridrik E. - Business Owner

Consult Your boqi LED Drivers Experts

We help you avoid the pitfalls to deliver the quality and value your LED drivers need on-time and on-budget.